LED lamp strings can be repaired. It can be as simple as replacing one failed bulb but can be more complex. Often it is not easy.

Early preventative maintenance, a dab of grease into each socket when new will help prevent corrosion caused failures. These strings could last much longer if the manufacturers did this for us at minimal cost. But you can do it yourself. Keep these strings running and out of the landfill.

**NEW** Mar 12 2020 Please see the Addendum for some updates and new pictures.

Don't LED lights last forever?

Apparently not, particularly when used outside.

Winter is very damp here in Canada. Water gets into everything, including supposedly sealed outdoor lighting. The water causes the LED leads to corrode and fail. This corrosion failure of LEDs due to water can be completely and easily stopped with a dab of grease, if caught early.

Failed bulbs that you can see should be replaced promptly since they cause the rest of the string to be under more stress and may lead to more failures. I had the kind of failed bulb that prevented the whole string from lighting. Both kinds of failure can occur.

Like most of us, I bought into the LED low power and eco friendly thing a couple of years ago. I threw out the old filament bulb outdoor Christmas lights and bought new GE branded outdoor LED string lights.

Yesterday, while getting ready to put up the Christmas lights, I found that two out of eight strings did not work. Each has 25 LEDs. I spent part of the day exploring why those had failed and putting up the rest. Fortunately I had tried them before putting them up!

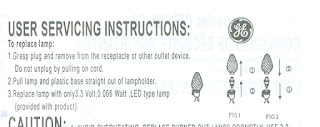

(click any pic to enlarge it)My GE strings are supposed to be repairable. They come with instructions (the full copy, a pdf) and spare LEDs.

The worst part about my two failed strings was that none of the bulbs lit up. Not one or two bulbs that weren't on while the rest worked. The failed bulb could not be seen since it kept all the others from lighting. This meant that each bulb had to be pulled and a working bulb inserted (according to the manufacturer's instructions).

I thought that we had abandoned series wired light strings back in the 60s? Series wiring is back with LED lights!

I can remember my dad back in the day proudly showing off a new parallel wired string, with which one failed bulb would not darken the whole string. He had spent many a time finding a failed bulb in a dead string so he knew the advantage of parallel wiring. From then until now, the advent of LED lighting, most of our filament bulb lighting strings were wired in parallel.

Series wiring is back with LED lights! It turns out that there is a technical reason why LEDs need to be wired in series and this will be discussed below. Since they are wired in series, I need to check every LED bulb if none of the string lights. Any one of the LEDs could be open circuit.

There are 25 LEDs in each string so that is 25 decorative caps to pull off and then 25 LEDs to pull out. Some of the caps come off easily, others do not. I found that a drop of WD40 helped free some of the stubborn caps. I dripped the lubricant onto the joint between the cap and the socket.

Some of the caps broke when I pulled them off, usually a part of the sealing ring was left in the socket. I dug out the debris from the socket and discarded those caps and replaced them with spares from the scrap strings. The caps are keyed and only fit on one way. Why they did this I am not sure.

I admired the first class molded parts that made up the socket assembly including the LED holder, the cap and the base. There was no flash and the parts fit together very exactly and securely with a snap. With ideal plastic that did not weather or change dimensions or properties with UV and temperature, these would be really nice parts. After a couple years outside, some are harder to get apart than others.

Pulling out the LEDs was sometimes problematic. I used my fingernails inserted in a small groove between the LED and socket and just pulled. Here also, a bit of lubrication from the dielectric grease helped with subsequent removals.

Throughout all this pulling on the socket, I tried not to pull on the wires. They seem securely crimped into the terminals but I thought it best not to pull too hard on them. The terminals are a potential point of failure so while the LED was out of the socket I took a look at the joint with the wires and the condition of the terminals before dabbing the grease and re-inserting the bulb. The inner (insert) portion of the socket can be removed and that will be described below. I found it was desirable to remove the insert on those where corrosion was seen in the socket.

It's about RUST

The cause of my failures was common corrosion. Each LED is itself encased in clear plastic but the metal leads that form it's connection with the socket are made of iron or steel and these leads rust if exposed to water and oxygen. The socket weatherproofing can be improved with a dab of dielectric grease to prevent the oxygen and water from reaching the point where two dissimilar metals touch: the LED lead (iron) and the socket contact (some other metal). Why wouldn't the manufacturer do that? If I doubted that the LED leads were ferrous, here is a picture of the rusted ones stuck to a small magnet. You can see a broken off LED lead in the foreground.I have opened all the bulbs on three of my LED strings so far. One that I scrapped had a high percentage of failed bulbs 8 out of the 25. Another that I did not scrap had only one of these problem bulbs. All of these bulbs failed because the LED leads rusted. Some of the LED leads had fallen off or rusted completely through.

Probably millions of these string lights will end up in the landfill over the next few years because people will give up on them. Hopefully you can use some of these ideas to help you to locate the problems with your own and keep them going for a few more years.

Understanding how LED string lights workYou do not have to cut the LED string apart and unwind it as I did here but it helped my understanding of how the thing was put together and I am going to use this picture to explain what I found.

Parallel wired light strings have two wires down the length of the string and each lamp is wired between the pair of wires. These LED strings have three wires down the length. It is a little difficult to see what is going on unless you do what I did with a string that was damaged beyond repair. I separated the string into two parts by clipping at only one point. I could then unwind the string into it's two sections as revealed in the picture above.

This is a schematic of my LED string. I clipped the wire at the bottom of the canister. The center portion, the string of LEDs, can then be separated from what I've called the extension cord portion. You can see in the schematic, the wires across the very top and bottom connect the plug at one end to the socket at the other. The series string of LEDs is inter-wound, but is separate from, the extension cord except at the very ends where the LED string and the canister join the circuit, across the two hot leads.So you can see the LEDs are all in a string and that if any of the LEDs fails open, the current flow in the string will be interrupted and the entire string will be dark. Unlike filament bulbs which rarely fail shorted LEDs can fail in this way. No light is produced yet current continues to flow through the LED. It is thus easy to see which LED failed since it will be the dark one.

It is interesting that in the GE instructions, they seem to presume that the LEDs will fail short and you should look for dark ones and replace them. This was not my experience. All of my failures were failed open circuit, due to rust.

I sacrificed two of the canisters to dissection for the cause of this project. You can see that my method improved after I learned to cut through the cover sheath at the joints of the inner cylinder. There are two 2000 ohm 1 watt resistors and a diode wired in series on a three section frame. Kind of a clever thing. No signs of water ingress with either one, unlike with about 10-20% of the lamp sockets. But I had to look to see what was in here.I'd like to point out the excellent writing of Terry Ritter "LED Christmas Lights and How to Fix Them". Terry has been down this road and he writes about how LED strings work and what he learned with strings made by Philips. These I have from GE seem very similar.

Terry describes that the LEDs are arranged in series strings because they do not tolerate high voltage well. The voltage that comes from a wall plug (120VAC in North America) is high voltage to an LED which normally operates from a few volts - 3.1 volts in the case of my white LEDs. By stacking 25 of them in a string, each LED drops 3.1 volts so the total voltage drop across the LED string is 77.5 volts. The resistors in the canister are used to drop the remainder (120 - 77.5 = 42.5 volts).

Interestingly, if LEDs fail short, they increase the voltage drop on all the other components in the series circuit so the resistors get hotter and all the other LEDs pass more current. So you can see why GE tells us to "replace failed bulbs promptly" because the whole string goes into overdrive mode if LEDs fail shorted. If they fail open, the whole string goes dark and no current flows.

Terry found that the Philips LED string contains a small fuse in the plug end. If the fuse blew, the string would not light. Do I have a fuse? No mention of a fuse in the GE pamphlet. I attempted to find such a fuse and went so far as to destroy the stacking plug end of one of my rejected strings. I think I can say with authority that there is no fuse in the GE unit. Maybe where Terry is, they need to have a fuse? You should eliminate that possibility, that you have a fuse. Sometimes the "fuse" is thermal and permanently cuts the circuit. Something like that would be in the canister, with the resistors.Terry talks about failed LEDs being dark and easy to spot, so obviously he saw lots of the failed short type. Not here. Terry wrote in 2007 so perhaps the LEDs are different now. He uses LEDs of different colors whereas mine are all white.

Terry also mulls the lack of a blocking diode in the Philips string and suggests that manufacturers add a blocking diode to better protect the LEDs from reverse transient voltages and it seems that GE listened to his advice and added such a reverse blocking diode in the canister.

Finally, Terry points out that running LEDs from AC means that the LEDs are only on for a part of the time leading to a flicking effect.

I attached a current meter to one of the wires in the GE LED string and displayed the results on an oscilloscope to show what Terry is describing.The green oscilloscope trace shows that most of the time (the flat part of the trace), the LED is OFF and for about 1/3 of the time, 60 times a second, the LED string conducts hard, up to about 44 mA maximum and then goes off again. 44mA is a lot of current for an LED of this size which would normally run at between 10-20 mA current if it was continuous or DC current. I suspect that the string would appear much brighter yet use the same cost of electricity if the string was operated from DC rather than AC.

I will look at that possibility in a future article.

Fixing the LED sockets

The main failure mechanism I had to deal with was rust in the sockets (rust is an insulator) and deteriorated LED leads.

The LEDs with deteriorated leads (any sign of rust at all) were discarded and replaced. Fortunately GE had supplied a number of spare bulbs (about six) with each string. Working ones from the scrapped strings provided more spare bulbs and caps.

The sockets were cleaned in the following way. I found that it was possible to separate the sockets into two parts by pushing out the inner section with a small blunt tool. You can lay the socket with its open face flat on a surface and push hard on the center, between the wires, to free it up. Then if you pick the socket up and push, the center portion should just come right out. This picture is a bit ugly with the socket guts covered with Vaseline, the dielectric grease I had handy. This socket was particularly badly coated with rust and the LED leads had completely disintegrated so it is the one I wanted to show you.It is interesting that in any galvanic pair of metals, it is one metal that corrodes and the other is fine (more about galvanic corrosion). In the case of these sockets, the LED lead suffers but the contacts are ok except that they are coated with rust. With the socket disassembled it is very easy to get at the top edge of the connector to clean it up. This one has been together for a while potted in Vaseline which seems to be lifting the rust residue which is fine, both the Vaseline and the rust are insulators. The point of the Vaseline is to keep water and oxygen away from the LED lead and the place it touches the conductor in the socket. You can see the bright metal edge on the socket conductor where I have scrubbed it with a small screwdriver to clean up the edge. It is only these top edges that touch the LED leads, you don't need to worry about cleaning up anything else. To re-seat the contacts, just push them back into the socket. They will click into place. The Vaseline helps to seal the joint where the wires enter the socket also.

Finally, I ran a bead of Vaseline around the base of the cap before inserting it into the socket. This improves the lubrication so the cap is hopefully easier to remove next time and the film of Vaseline would help to seal the joint between the cap and the socket, helping to keep out the water.

Hopefully these lights will continue to give good service for years to come.

Your comments are welcome. Thanks for your interest and good luck with your LED light strings.

George Plhak

Lion's Head, Ontario, Canada

**NEW** Mar 12 2020 Please see the Addendum for some updates and new pictures.

You might also be interested in my series on

a very bright 1 watt diy led garden light

50 comments:

A couple of things...

1. All "Miniature" Christmas lights are wired in series, the difference is that the modern (post 1960-1970 something) ones have a loosely wrapped and lightly insulated shunt inside each bulb that "kicks in" (welds itself across the inputs) when the filament fails, keeping the rest of the string lit. As with the LED strings, it is imperative that dead bulbs be replaced immediately to avoid the rest of the bulbs in that string being overloaded.

I work for a large distributor of light strings, and am currently working on a solution based upon a CL220 current regulator from Supertex, Inc. It will take any input voltage from 5-220V and will drive any number of LEDs in series so long as the total forward voltage does not exceed the supply voltage.

Let me just say that this chip is awesome, the light output is increased, there is no flicker, and even though it has three pins, you only use two, you simply wire it in series just like a fuse, and it automatically limits the current to 20mA no matter the input voltage, number, color or manufacturer of your leds. What could be simpler? You can find more info along with many other LED solutions at:

http://www.supertex.com/feature_LED_general.html

Go to the website and request a free sample!

Did that sound like a commercial? I can assure you that I do not work for them, but after requesting a free sample, getting it in 3 days, and seeing the results, I am very impressed. They also had a rep contact me and he has provided circuit details for our specific application.

Here in CA, and hopefully the rest of the world, we should be seeing LED light strings live up to the promises - they are really bright (even at a measured draw of only 19.6 mA), have no flicker, no reverse voltage, and no stress from surges/ESD (when combined with an MOV, a bypass cap and a filter cap).

So far (only about one week of continuous use) there is no visible signs of failure. And the price at Mouser is only $1.43 for single units.

http://www.mouser.com/search/refine.aspx?Ntk=P_MarCom&Ntt=109749218&utm_source=supplier&utm_medium=featured+spotlight&utm_campaign=109749218

Chris

Thanks for the info - I read mr ritters article too and still not sure if I can fix my squirrel-chewed lights . The squirrel has chewed thru the wire directly at a bulb on each of my stings. I could not splice the light since it was at the light, only I had to cut out the light. I soldered the wires together w no luck. My brother suggested removing a second light, saying sometimes circuits are every other one so I did that but it to did not fix the light. So one half of each string will not light up. Am I understanding from your article that if a single bulb is removed the voltage is too high for remaining bulbs n they will burn themselves out? So I have too much juice running thru my string now? If so could I perhaps use this string as my stock and replace the chewed lights (entire lights w wire ) and splice them into the remaining damaged cords?

Thanks for your interest Heather. It sounds like probably the best thing is what you suggest, to use the damaged strings as your repair stock.

orshowc 122Thank you very much for this information. Actually I live near sea sied and I do face these problems onces in a month so now I can fix them by my self

I WANT TO KNOW HOW TO MAKE FILAMENT RICE BULB ROPE LIGHT.I WANT INFORMATION FOR WHAT TYPE OF MACHINES AND FROM WHERE I GET THAT MACHINE. ALSO NEED INFORMATION FOR THE SOURCES OF BASIC RAW MATERIALS.

I shuddered at you suggestion that LED Christmas lights could run off DC. Unfortunately, some already do, and spew Radio Interference (RFI) "Hash" across the radio spectrum!

The culprit is the cheaply made, non-filtered switching power supply used to convert AC to DC. You usually find it in a small box attached to the plug. They don't have to be so poorly designed- but being made in China, where they don't care about regulations, and few pennies are saved by leaving out good design requirements.

All these cheap, unfiltered, unshielded boxed switched mode power supplies (SMPS) and digital electronics are destroying our Radio spectrum by increasing the noise floor and wiping out full sections of the radio frequencies.

Even AM Broadcast radio stations are now having to increase transmit power or move to FM because that band is becoming useless. I wont even get into the cost (financial and opportunity) to the full shortwave and UHF/VHF spectrum!

Thank goodness all theses LED Christmas lights have not gone to a SMPS. Their long wire leads would act as an antennae for all the radio interference they would illegally be "transmitting" into the ether and into a radio near you. Imagine- with all the lights hung in all the neighbourhoods- the effect it would have!

I prey that day never comes.

This is an informative article, because I was curious about whats inside an LED light string.

There seems to be some errors though.

When calculating the voltage acros the resistors, he used an input voltage of 120 V RMS, it should be volts peak, 120 V RMS x 1.414 = 169.7 V Peak.

I calculated the following.

The peak current is:

I Peak = [(V IN RMS) x √2 - (V LED) x 25 - V Diode]/R

I Peak=[120 x √2 - 3.1 x 25 - 0.7]/4000

I Peak=[169.7 - 77.5 - 0.7]/4000

I Peak=0.023 Amps

23mA is way lower than his measured current of 44mA.

If you take his current measurment of 44mA peak x 4000 ohms = 176 V peak.

Now add the voltage across the LEDs: 176V + 77.5V = 253.5 V peak, which is not possible with 169V peak input.

I think there is an error in his current measurement.

Thank you Gary.

You are correct about the peak voltage being higher than the RMS and that I should have used that value. My point was to illustrate how the voltage was divided by the string. I didn't actually measure the 3.1 volts per LED either, that was an estimate so that could be incorrect also.

On the current scope shot, I was trying to illustrate that the current flowed for only a short fraction of the cycle and that DC drive might give better results, less flickering, more brightness and longer bulb life. I will do some more work on this. Thanks for correcting my math and for your interest.

George

I am very happy to find this on the web. I have always wondered what was in the really cheap strings. THANK YOU.

One of the comments was about a "cheap" switch mode DC source. Yes, very poor engineering. However, using a full wave diode bridge and about a 2.2 uf, 400v capacitor, the 25 LED string with the 4K ohm resistor would be more than 3 times brighter. I don't think the continuous 23 ma would be a problem, but the two 2K resistors may not take the continuous power. Likewise, replacing the resistors with the correct wattage, may cause the plastic canister to melt!

Anyway, the reason I’m interested is because I want to make a “real” LED lighting system for the home (kitchen). MY switch mode DC current source will be a Cuk converter -- or at least some proper, near "1" power factor design that passes UL and FCC regulations!

My problem is not the electronic design, but the really cheap UL approved hardware. I'm going to start with a string of white Christmas lights -- that will give me a polarized set of sockets. I reduce the series to only 12 LED's for about a 40VDC compliance from my (variable) 20 ma, isolated, UL and FCC approved current generator. (I need to research this. 40VDC may be to high to be considered “door-bell-wiring safe“.)

I won’t go into the details here, but my objective is to make a safe, isolated, low voltage, DYS, LED lighting system for home use. NOT the present expensive, electrician installed, industrial LED lighting systems.

For the record, I would love to have a self-adhesive (stick them anywhere), polarized socket, with some sort of insulation displacement wire ports and a momentary shorting switch (when the LED is pressed).

I like the idea that Christmas lights can be replace by novices because of the “spare” LEDs in the polarized holders!

Also, a press-to-short socket will allow easy testing for an “open” LED in the string.

Note: shorting an LED in a string driven by a current generator will not change the current -- BUT it will change the voltage at the “generator” by about 3 volts. I hope to make the isolated current generator “smart”.

Momentarily shorting one LED will be like a “mouse click”, signaling the current generator to change something -- like dimming/on/off.

Another method manufacturers could use to increase the brightness of the led string is to connect another led die in anti-parallel (a.k.a back-to-back)with the first die. Then one die would light on each half cycle. The flicker would still be there but the apparent rate or flicker frequency would be higher and due to POV would be less objectionable as well.

73 DE Andy WA8ZLK

A few years ago when I brought out our LED lights, I discovered water still in the bulbs from the precipitation the previous year. I also noticed that the lights were very dull. I took out the lights and discovered the rust so I used rust remover to clean the rust off the bulb and socket and put them back which resulted in a much brighter light. However every year it's the same issue. I'm glad to finally hear someone address this problem. My question is, is it ok for the Vaseline to come in contact with the bulb contacts? ...stay inside the socket?

Yes, it is ok for the dielectric grease (I used Vaseline) to be in contact with the socket and bulb. The grease keeps the water from contacting the metals, preventing corrosion.

Frank said...

Hi George

I Goggled how to repair LED Christmas Lights yesterday and eventually ended up at your site. Thank you for the detailed explanation and the pictures. This morning I took the lights back down and proceeded to pull the lights apart, a little spray of CTC silicone seemed to free up the covers and then I had to check about half of the string. I envisioned them going in the garbage when I started. However, true to your word there was the culprit two corroded LEDs, little brass brushing, vaseline and voila- we have lights. Of course it is much colder today so way better to go out and rehang them today.

Thanks again and have a very Merry Christmas

Cheers

Frank

Pickering Ontario Canada

All of this is very interesting, but I want to ask about 2 specific light problems. This is the 1st year I've used LED Christmas light strings. After about 2 weeks of perfect operation, one string lost all lights in the first half of the string, and a second string lost 8 contiguous lights in the middle of the string. I am guessing the first string has a fuse issue since there are 2 fuses (one per 1/2 string). The second string (with the 8 bulbs out) seems to be related to the fact that they are all the 8 lights between 2 "diode containers" (cylinders about the size of a 1st grade pencil and 2" long). Is there anything I should do to fix this second string by replacing something in one of these cylinders? I guess you can tell I'm not an electrical expert. Thanks, Rob

Hello Rob. Since this is the first year you are using these lights is it safe to assume they are new and still have warranty? Should you return them for a refund? What brand are they? It sounds as if yours have several parallel strings since 8 lights went out in the middle. Are there three wires down the length? Are the two strings the same since it sounds as if they may be wired differently. If you want to troubleshoot, you will need to trace out the wiring and determine what is inside the "diode containers". You will likely destroy these by opening them or at least break the seal so if fixable, you will need to come up with another weatherproof housing. Please use care! If you can return the strings, I think you should. We should not be buying crap like this and the manufacturers should get them back.

I can identify with all these comments. I have about 200 running feet of LED icicle lights on my house.For 2 years- beautiful. 3 years later, I'm ready to throw them out. But I did buy a tool- LED LightKeeper for about $25. Unplug the string, plug into LK and the tool pierces the wire in the unlit section. If all goes well, the good part of the string will light up indicating that somewhere behind that location is a bad LED. Move the tool backward to new locations and thru process of elimination, you find a bad LED, replace and off you go!! Well, not quite. If there are multiple LED's out, it takes a little patience and I had a number of them. Rust would knock out 2-3 diodes in my 30 bulb sections. And twice, I had diodes that only lit when reversed- the whole string would be out because one diode was in backward. Not sure how they worked last year and this year they are reversed, but I found a few. Also, found that the tool often didn't pierce my wire, I would pull trigger several times and it just wouldn't make contact with the copper wire. I finally gave up, put a small wire in the piercing clamp, used a rubber band to hold the trigger closed and then would stick the other end of the wire into a diode socket to see if I had continuity. It worked much better, easier to pull diodes and check while strings were on the house. Most of my sockets are rusty, I look thru the lens and can see some discolor, I check them first and replace, then get the tool out next. Got all mine working and they have looked for the last 4 weeks, I'll get them off the house soon and hope they didn't rust anymore this year. Paid almost $250 for these lights 5 years ago, hate to get rid of them, but it's taking lot's of time to keep them going each year. Wife loves the lights, I love my wife!! I guess I'll keep fixing.....

Thanks Gary VDW. I deleted your second identical comment. Readers can find the LED Lightkeeper with Google. I personally don't like the idea of piercing the wire to get a connection since this makes a hole in the insulation letting in moisture and the copper conductor wire will eventually corrode and fail. The whole problem is moisture right? Thank you for your detailed comment.

I agree with your assessment of the wire piercing, the idea of taking a short section of wire and piercing that in the tool with the trigger held closed with rubber bands and then pulling a diode and sticking the other end of the short wire into the socket eliminated the string wire piercing. It worked for me and worked well. I can spot problems so much quicker now and I'm sure the tool is engaged with the circuit I'm testing.

I purchased the 'LED Keeper' with the expectation I'd quickly drill-down on the problem site causing a section (or more) within an LED icicle strand not to light. It's turned out to be an enormous disappointment, and simply adds more frustration than it resolves. The product is simply an in-line (i.e., "wire piercing") continuity tester, and features a built-in LED tester.

Similar to the experience reported within this blog, I find that it takes many piercings attempts to contact the wire conductor--most times it simply doesn't, and no LEDs illuminate. Even more frustrating the various scenarios one might encounter when troubleshooting a problematic strand of lights with their LED Keeper. For instance, I often find instances where the LEDs illuminate, but are very dim; or a specific number will illuminate at varying brightnesses. The LED Keeper support website leaves much to be desired as a resource when one experiences phenomenon outside of the ideal fault situation; i.e., a single bad LED within a section. The LED Keeper is just a very limited-use tool. Bleh.

I tried the "pierce-a-wire-with-the-trigger-held-down-with-a-rubber-band" method suggested within this blog, but that simply produced more of the same weird behavior, LEDs of varying brightness, without really helping to narrow down a specific source of the fault within a problem area of a segment.

LED owners and maintainers need a tool that tests ALL the various problems that may affect a strand as detailed on the following website: http://tinyurl.com/7weou9u. The sets are simply too expensive to summarily chuck when out of warranty; whilst maintaining them using the "swap-out-known-good-bulb-socket-by-socket" (which only works in single bulb failure scenarios--the rarest type of failure with LED lights sets). For years, telecom techs have used RF transmitter/remote receiver combo devices to trace wire faults. We need a device like that for fault testing LED strands.

We just purchased 3 strings of C9 LED outdoor lights. They each lit up independently so we strung them up without checking them plugged together. They're up. And the middle string does not light at all but the other two do. Never had lights with fuses before. Is this the problem? Fuses on the centre string? It's cold out there and I'd like the info before I send him back up the ladder - thanks!!

Hi Lynne, you don't say how the three strings are plugged in. Are they plugged into each other in a long string or do the three all plug one end at the same feed point? If they are new lights, you should have warranty? As I noted in my article, newer strings do no seem to have fuses.

Thanks for your reply George. They are plugged into each other to go around the eave of the house. There are fuses in the strings and there are 3 wires per string.

Thanks, Lynne

You found fuses. Was that the problem with one of the strings? Was the fuse difficult to replace? I'd be interested in the brand of light. Thanks.

Success at last! We took down the faulty string and returned it after checking the fuses - which were fine. Of course they were out of the length we needed but gave us 2 shorter ones at a discount for all our problems.

Lights were Home Accents 'Holiday' sold by Home Depot. 25 LED C9(largest size) lights.They have 2 fuses on the male plug of each string. Three green wires per string.

Only lessons learned were

l. Test the lights at the store- by the pkg and then connect them to each other

2. Keep your receipt and packaging - you have to store them anyway

3. They are guaranteed by Home Depot for 90 days and by the manufacturer for 3 yrs

Hope this is useful and helps someone else

Glad you were here and thanks

About the fuses.......they are protected by a sliding cover which you move towards the prongs. They are about half an inch by a sixteenth cylinder and you can pop them out gently with a very small screwdriver. My hubby got very good at that as he had to check the fuses in several places. The fuses were not the problem.

Lynne

Good information in comments, after that long ramble. Thanks.

Thanks Jeffrey. I think you mean after my long ramble in the article perhaps? :) A complicated subject. This article gets a lot of viewers this time of year so I hope it is helping some.

Slightly different issue than I've seen in the article and comments - we bought Sylvania 3 way led lights last year, and they worked great all season... This year, we tested them, all worked, so we put them on the tree and enjoyed for about 2 days before they stopped working. We have three strings of 100 connected to each other and none of them are working. We thought it could be the little 3 way control box, so we replaced it with another one and the lights blinked on for about a millisecond and then nothing. No lights.... We tried plugging in the other two strings independently thinking maybe it was just the bottom string, but those aren't lighting up either. The packaging says that if any bulbs are out, the rest should still light up, so we don't think it's a bulb issue. Any ideas?

Also, meant to mention that we checked the fuses - they are fine.

Hello Leah. Sylvania has a product called "Sylvania 100-Count LED Mini Lights 3 in 1 Synchronized Color Changing". I found them on Amazon here. The controller is not shown but I see the special connector.

I notice in reading the reviews that several people have had a similar problem to yours, particularly the one by Ross Campbell Dec 2014. I think this might be a warranty issue with Sylvania? Good Luck.

Hi George, thank you for putting this article together (it was the only relevant one that came back in my search). I just pulled one of my LED Icicle lights out and the socket is covered in rust. Saw that you recommended Vaseline as a cleaner for the rust... is WD40 a safe alternative do you think? Rather not burn my house down because we lack Vaseline to clean em with!

George - Thank you so much, we called Sylvania and they're sending new controllers... fingers crossed!

Help I have c9 led lights worked great last year put them around the house this year half the strand works great the other half very dim. Almost like they are not working checked each bulb work but dim. No corrosion in the sockets.

I easily fixed two or three strands, each of which was half out. I located the faulty bulbs with a non-contact voltage tester which tells you there is voltage (AC) on one side of the faulty bulb but not on the other. The faulty bulbs had corroded steel leads of course (Ahhhhhh!) which immediately fell off. Manufacturers maybe you could please start using copper leads! One strand had replaceable bulbs so I just plugged in a new one, the other didn't so I just cut that bulb out, which I know will stress the others a little bit. I have never seen the case where only one bulb is out, but I believe it can happen because George said so.

My question is about the other three strings I have: 1. no lights on so where to start testing, 2. half faintly on, 3. faulty bulb has three wires coming out of it.

I easily fixed two strings each half out, by locating the faulty bulbs with a voltage tester. Of course the leads just fell apart from corrosion (Ahhhh!). Hey Manufacturers how about making the leads out of copper? In one I could just plug in the replacement bulb, and in the other string I just cut that bulb out. I've never seen the problem of a single bulb not lighting and the string still on (closed short?), but I believe it happens 'cause George says so.

I am still left with: 1.a string with all bulbs out (where do I start testing) 2. a string with half the bulbs dim, and 3. a string where the faulty bulb has three wires into it. I don't get the environmental savings if millions of these strings are going into the landfill each year.

I have GE LED mini lights that I bought in 2012. They have fuses. I bought 4 and 2 of them have gone very dim. They are on, but very dim. Otherwise, I have had several individual light failures over the years, that don't seem to effect the rest of the string. Initially I would replace the failed bulbs, but the strings that I did that with are the ones that have gone dim. Of the 2 strings that I didn't bother with, they still work. I took out all the lights on one of the dim strings and I see no rust at all. My husband doesn't think that the dimness is a faulty fuse.

I fixed my dim lights. The whole string of lights would be dim. I removed all the lights, so I could inspect each one. They didn't have any rust, but some did have a little white corrosion. The main problem was that many of the LEDs had broken or loose legs. I replaced these with intact lights. You can either buy replacement lights or replacement 3mm LEDs for super cheap on eBay. Using LEDs is simple. The xmas lights are in 3 pieces: base, cover, and LED. Take the cover off, straighten the LED legs, slip the LED out, put a new LED in, making sure the short leg lines up with the upper hole, bend the legs up, and snap the cover back on. New replacement bulb! For the corroded sockets, I sanded them a bit until shiny. If they weren't sanded enough, that individual bulb would not light. Then I put all the bulbs back in the string and voila! It's not difficult, but it is a bit tedious. The only tools I used were a pair of pliers and sandpaper.

No, no, no! I just repaired a string of GE LED lights and it's wired nothing like this. Reading the above comments, did you wonder why, if clever people can add rectifier and reversed-polarity LEDs to make a string work better, GE can't? Of course they can, and have! I'm cannibalizing and reconstituting strings from which squirrels have excised individual lamps. (Apparently, millions of years of co-evolution with gymnosperms makes even tasteless, nutritionless cones irresistible as long as they light up!) Here's what I've learned:

These are strings of 25 pair of sockets, 50 sockets but of 2 alternating orientations forming discrete symmetric sub-circuits, the sub-circuits wired in series. Member of a pair are connected by 2 conductors; adjacent pairs are connected by 1 conductor. The string includes 2 more conductors connecting plug to receptacle without impinging on any socket. (Between any 2 adjacent sockets, therefore, are either 3 or 4 wires, 2 of which bypass both, as well as all others.) Mains prongs are fused. In each plug and receptacle are 2 diodes which, together with the bypass conductors, constitute a bridge rectifier. (If this sounds like I know what I'm talking about, don't be misled. It's very basic.)

Think how clever this scheme is: the LEDs are operating at 120 Hz rather than 60 Hz, all but eliminating flicker and enhancing both longevity and efficiency; both LEDs of a handed pair (both the right and left *of the same sub-circuit*) must fail for the string to go dark, greatly enhancing reliability and fixability; and I suspect some of the risk of daisy-chaining strings is alleviated by the presence of continuous bypass conductors.

It makes splicing in lamp sockets a puzzle. (Squirrels don't remove the LED seed, they snip off, cart away and hide the entire cone.) For full function the correct handedness and wire assignments must be replicated and visible clues to those are subtle. Intriguingly, getting it wrong isn't catastrophic. Using the wrong polarity socket means that lamp won't light, but either all of the others will or all but its twin will, depending on whether you also wired it backward. In other words, you can get a lot wrong and 96% of the string will still work. And the possible combinations aren't many so systematically trying them all works if the pattern is hard to discern. Happily, that means the LEDs are identical except for color. To achieve polarity-paired LEDs, using hardwired handed sockets (with keyed orifices so LEDs can only be inserted one way) allows the use of fully interchangeable LEDs you can prise out with a fingernail. Until you start snipping and soldering as I'm doing, that makes repairs simple.

Wow! great blog! I love when people exchange ideas like that!

This has been really educative.

I have lots of tips and tricks about lighting repair too. If you feel like it, you can check it out at: http://allainthebrids.blogspot.ca/ or on Facebook at: https://www.facebook.com/Allain-The-Brids-795853243883898/

keep up the good work guys, I love reading your posts!

Hi George, thanks a ton for this information! I believe I have a reversed socket as you explained above – just one bulb is out and Winn replaced with a working bulb, it comes on very dimly and then dies. The wires into the socket did not appear to be reversed compared to the other sockets, however the plastic tab faces the other way, matching your second example above. I was hoping you might give a little more detail on how you fixed the problem? I'm interested in attempting it, but I don't think I quite understand what you were doing. :-) Sorry for the anonymous post but very grateful for any light you can shed on this! (ha ha) --Margret

Very helpful!

Maybe one of the other comments already mentioned, but you should avoid Vaseline as a dielectric if you can. It's melting point is just above body temperature so, on a hot summer day, it can get runny and potentially dry out over time.

Thanks for taking the time to post all this info. Currently working on a similar project with a different brand (color-changing RGBs) and will do the same!

The Microchip SL220 LED constant current driver¹ Chrisman mentioned back in January of 2013 is still available. The links in Chrisman's comment are no longer valid but the product is still available. Microchip sells it for $0.79 each/5,000 pcs. Note that the SL220 was originally a Supertex product Microchip was distributing until Microchip bought Supertex in February of 2014². Mouser continues to market the CL220 under the Supertex/Microchip name³.

______________________

¹ https://www.microchip.com/wwwproducts/en/CL220

² https://www.microchip.com/investor/Pressrelease/MCHP%20Announces%20Acquisition%20of%20Supertex,%20Inc.021014.pdf

³ https://www.mouser.com/search/refine.aspx?Ntk=P_MarCom&Ntt=109749218

https://georgesworkshop.blogspot.com/2019/04/series-parallel.html

Well done George! I appreciate and admire your attention to detail! Several years ago I bought 5 garland strands roughly 8 feet long. After a few years bulbs started failing and then, you know how that goes, I'm like the dad in "Christmas Story" movie, cussing to myself. So 4 years ago I bought 3 more garland strands from Costco, LEDs!, so "hurray" I thought. 2 years later a Costco set failed and I salvaged one set to repair the other 2 strands (i.e., to swap dead bulbs). This year I was committed to buy a new strand of mini lights (LEDs) and weave them around the garland, but beforehand I was compelled to try 1 more time to fix the remaining burned-out bulbs. Oddly, on the same strand, there are 2 styles of bases (as in the photos via the attached URL). On the "main" line from male plug to female outlet, there are 4 bulbs where 4 wires intersect at the base. These 4 are "shorter" bulb bases. I assume I can disassemble another common/longer base and carefully remove the LED and reinsert it into the shorter less common base... but then I ask myself, "why did the mfgr" use a different base if the LED is the same?" Seems completely unnecessary if the LED bulbs are exactly the same. So, questions are:

1) why use different bulb bases on the same light string?

2) can I remove an LED from a "longer" base (roughly 200 LEDs this style) and install the LED bulb into a "shorter" LED (of which there are only 4, always next to a (presumably) resister canister?

3) if I were to replace the LED strand and wrap it around the garland, what brand/model do you recommend (I'm in Northern Cal) for a fairly mild climate. Of course, the lights are used for a month or so. Rain here yes, snow, no.

THANKS ever so much

Link to photos:

https://photos.app.goo.gl/ZCEcNSu9M9QcWKMW6

Hey George... thanx for the article. I am wondering why mfr ( or ourselves) couldn't just add a few more lights to the string to get rid of the required resistors.....then use a small bridge rectifier to get rid of the 60hz flickering? Jeff C

Thanks George for the schematics and explaining how the whole thing works. I recently bought GE LED strings similar to yours (mine have fuses though, so it seems they've updated that), and after just two weeks they have failed. I pulled out a few bulbs, and just like your photos there were varying degrees of corrosion on quite a few of the bulbs and sockets. Sadly these are advertised as indoor/outdoor, which I think is false advertising.

This is awesome!! I’ve always enjoyed reading your blog.

Hyundai Tucson Parts Australia

Hyundai Parts Australia

Thanks for sharing an awesome blog

Keep it up and visit us

Motorcycle accessories Wholesale in Red Deer

Really i like the way of your blog post content, it's a good information..

commercial electrical services

ceiling fan repairs services

Post a Comment